Processing information

Important tips for handling our productsThe following processing instructions are general tips and apply to a large part of our standard range. However, as there are of course some exceptions, you should always follow the product-specific application instructions. If you are missing the relevant information, we will be happy to help you.

Abrasion resistance

- To achieve optimum adhesion, the substrates to be bonded must be clean, dry and free of grease.

- Anti-adhesive surface substances such as dust, mold release agents, greases or waxes must be removed before bonding.

- If possible, ensure that the substrate is free of plasticizers.

Unevenness

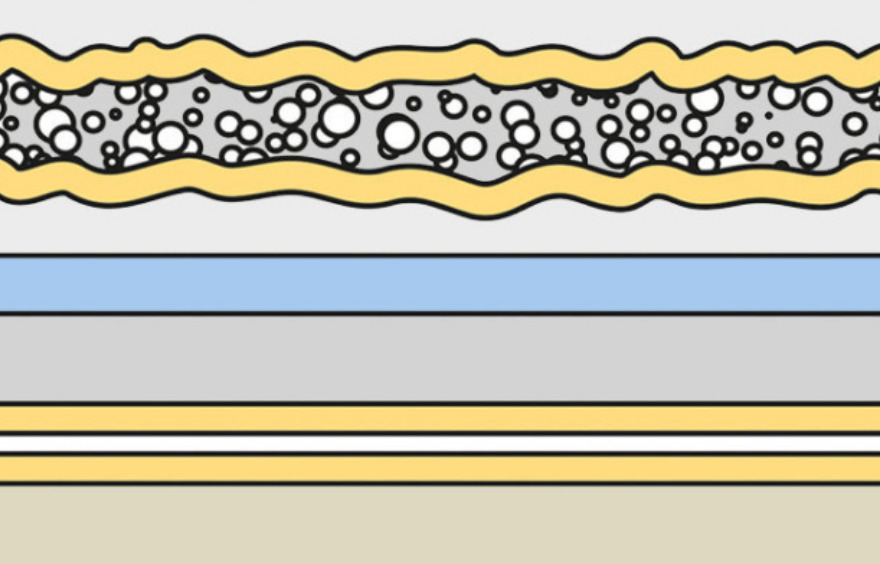

- For rough and uneven substrates, use thicker, leveling adhesive tapes.

Temperature

- The optimum bonding temperature is between 20 and 30°C in dry rooms. If possible, do not work at temperatures below 10°C

Application

- The separator cover must be completely removed.

- After joining, press the workpieces together with sufficient and uniform contact pressure (approx. 20 N/cm²).

- For optimum bonding, use a pressure roller.

- Ensure that processing equipment (including hands) is free of release agents.

Final adhesive strength

- To achieve the generally higher final adhesive strength, a mounting time of up to 48 hours is necessary.

Storage

- Store the tape in its original packaging at room temperature (optimum: 18°C and 55% relative humidity).