Verarbeitungshinweise

Wichtige Tipps für den Umgang mit unseren ProduktenDie nachfolgenden Verarbeitungshinweise sind generelle Tipps und gelten für einen großen Teil unseres Standard-Sortiments. Da es aber natürlich auch einige Ausnahmen gibt, sollten Sie immer die produktspezifischen Anwendungshinweise befolgen. Sollten Ihnen entsprechende Informationen fehlen, können wir Ihnen gerne weiterhelfen.

Abriebbeständigkeit

- Um eine optimale Haftung zu erzielen, müssen die zu verklebenden Untergründe sauber, trocken und fettfrei sein.

- Antiadhäsive Oberflächensubstanzen wie z.B. Staub, Formtrennmittel, Fette oder Wachse müssen vor der Verklebung entfernt werden.

- Nach Möglichkeit die Weichmacherfreiheit des Untergrundes sicherstellen.

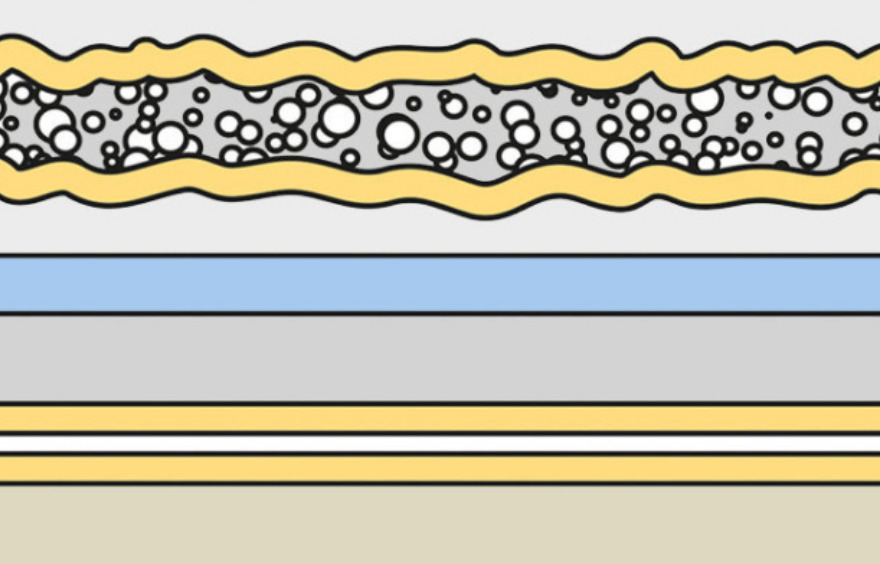

Unebenheiten

- Bei rauen und unebenen Untergründen dickere, ausgleichende Klebebänder einsetzen.

Temperatur

- Die optimale Verklebetemperatur liegt zwischen 20 und 30°C in trockenen Räumen. Nach Möglichkeit sollte nicht bei Temperaturen unter 10°C gearbeitet werden

Applikation

- Die Trennabdeckung muss vollständig entfernt werden.

- Die Werkstücke nach dem Fügen mit ausreichendem und gleichmäßigem Anpressdruck aneinanderdrücken (ca. 20 N/cm²).

- Für optimale Verklebungen verwenden Sie eine Andruckrolle.

- Auf trennmittelfreie Verarbeitungsgeräte (auch die Hände) achten.

Endklebkraft

- Um die in der Regel höhere Endklebkraft zu erreichen, ist eine Aufziehzeit von bis zu 48 Stunden notwendig.

Lagerung

- Lagerung des Klebebandes in der Originalverpackung bei Raumtemperatur (optimal: 18°C und 55% rel. Luftfeuchte).